Lift Innovation Universal, LLC, is a premier provider of cutting-edge oilfield chemical solutions, recognized for our commitment to innovation, efficiency, and sustainability. With decades of expertise, we have become a trusted partner to the oil and gas industry, delivering comprehensive and customized chemical services designed to address the unique challenges faced by operators in exploration, production, and refining.

Our portfolio spans the entire value chain, from extraction and transportation to refining and beyond. Leveraging our advanced technologies and research-driven approach, we develop and deliver tailored solutions that empower our clients to optimize production efficiency, reduce operational costs, and maintain environmental compliance. Whether it’s enhancing oil recovery in mature wells, preventing wax and scale deposition in pipelines, or refining heavy crude into high-quality products, our solutions are engineered to ensure reliability and performance in even the most demanding conditions.

At Lift Innovation Universal, LLC, we understand that no two operations are the same. That’s why we prioritize collaboration with our clients, taking the time to analyze their specific operational needs and challenges. This partnership-driven approach enables us to design and implement highly effective chemical strategies that improve flow assurance, enhance asset integrity, and maximize resource recovery, all while minimizing environmental impact and downtime.

By combining innovation, technical expertise, and a steadfast dedication to quality, Lift Innovation Universal, LLC, is not just a service provider—we are a partner in driving sustainable growth and operational excellence across the global oil and gas landscape. Let us help you achieve your operational goals with confidence and efficiency.

Fluid Separation: Advanced demulsifiers and dispersants for effective and rapid oil-water separation, ensuring optimal recovery.

Flow Assurance: Innovative wax inhibitors, scale inhibitors, and viscosity reducers to optimize oil and gas flow, minimizing pipeline blockages and downtime.

Integrity Management: Proprietary corrosion inhibitors and biocides protect oilfield assets, extend equipment life, and prevent microbial-induced damage.

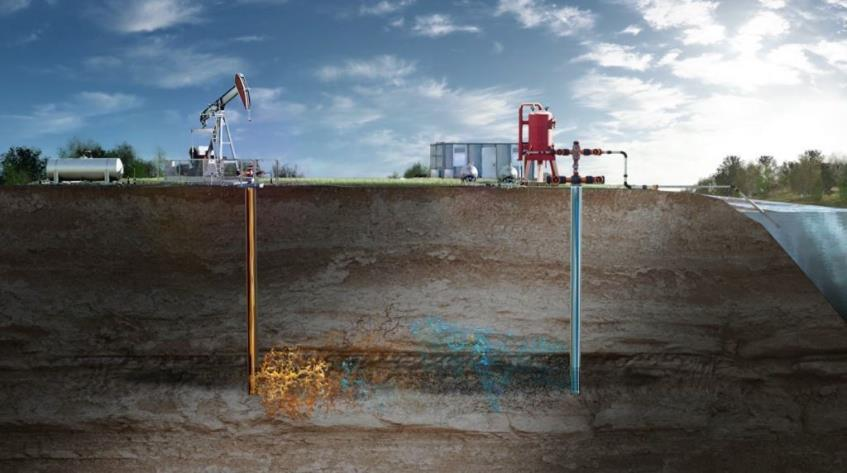

Enhanced Oil Recovery (EOR): Advanced technologies, such as chemical flooding and near-wellbore restoration, improve production rates and maximize recovery.

Customized pour-point depressants, wax inhibitors, and lubrication enhancers to optimize refining processes and enhance fuel quality while reducing operational costs.

Specialized solutions designed for challenging environments, including hydrate inhibitors, swelling inhibitors, and scale inhibitors, ensuring safe and efficient production in unconventional and deepwater operations.

Our drilling and cementing chemicals are designed to enhance operational efficiency, improve wellbore stability, and address the challenges faced in complex drilling environments.

Thickeners: Engineered to increase drilling fluid viscosity and stability, our thickeners ensure optimal performance in controlling fluid loss and maintaining pressure during drilling operations. These additives enhance wellbore cleaning and provide better suspension of drill cuttings, even in high-temperature and high-pressure conditions.

Fluid Loss Additives: Fluid loss can compromise wellbore stability and increase operational risks. Our fluid loss additives are developed to minimize filtrate invasion into the formation, protecting the integrity of the wellbore and ensuring efficient cementing processes. These additives are adaptable to various drilling fluid systems and challenging geological conditions.

Shale Inhibitors: Preventing wellbore collapse in shale formations is critical to drilling success. Our shale inhibitors reduce the swelling and dispersion of reactive clays, stabilizing the wellbore and optimizing drilling efficiency. This improves operational reliability and reduces non-productive time, even in highly reactive formations.

Our production and transportation chemicals ensure the seamless flow of hydrocarbons from the reservoir to the refinery, addressing common challenges such as flow restriction, corrosion, and microbial activity.

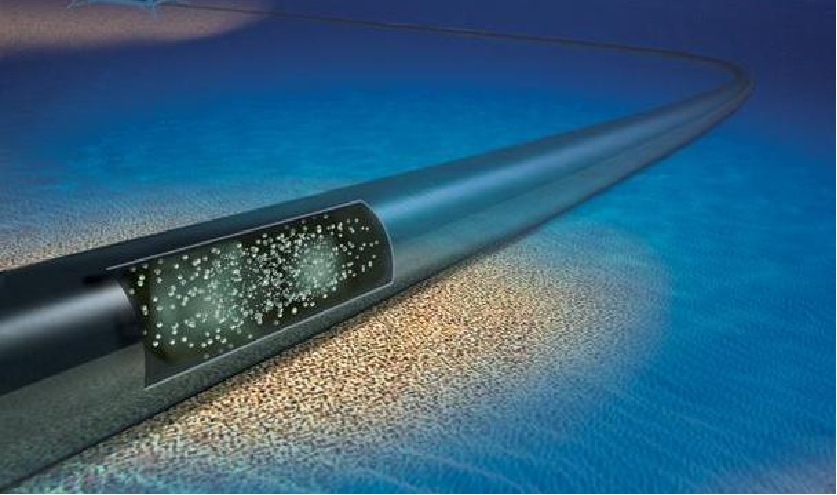

Wax Inhibitors: Wax deposition can significantly impede flow in pipelines, leading to operational delays and increased maintenance costs. Our wax inhibitors prevent wax crystals from forming and adhering to pipeline surfaces, ensuring smooth and consistent operations across varying temperatures and flow conditions.

Viscosity Reducers: Our viscosity reducers are designed to lower the viscosity of heavy and paraffinic crudes, making transportation more efficient and cost-effective. By reducing energy consumption and pipeline pressure, these solutions help operators optimize their logistics while maintaining crude quality.

Scale Inhibitors: Scale formation can damage equipment and obstruct flow paths, leading to costly downtime. Our scale inhibitors effectively prevent the precipitation and deposition of inorganic salts, safeguarding pipelines, wellheads, and processing equipment while reducing maintenance costs./p>

Biocides: Microbial activity can cause corrosion, fouling, and even blockages in production and transportation systems. Our biocides target and control microbial growth, protecting infrastructure from biofilm formation and microbiologically induced corrosion (MIC), ensuring long-term operational integrity.

Our enhanced oil recovery solutions are designed to unlock the full potential of mature and challenging reservoirs, maximizing recovery rates and operational efficiency.

Near-Wellbore Restoration: Aging wells often experience production declines due to formation damage and blockages. Our tailored surfactants and wetting agents penetrate deeply into the reservoir, restoring permeability and enhancing oil flow. These solutions are highly effective in rejuvenating well productivity.

Chemical Flooding: Advanced chemical flooding formulations, such as surfactant-polymer flooding, improve sweep efficiency and increase oil displacement. These techniques are designed to mobilize residual oil and drive it to the surface, significantly boosting recovery rates while maintaining reservoir integrity.

Heavy Oil Separation: Heavy crude presents unique challenges in flow and processing. Our proprietary viscosity reducers and asphaltene dispersants improve the flow characteristics of heavy oil, enhance separation efficiency, and reduce the energy required for transport. These solutions allow operators to process heavy oil more effectively, unlocking greater value from challenging reservoirs.

Our flow assurance chemicals are designed to address the critical challenges of maintaining smooth and efficient hydrocarbon flow through pipelines and production facilities, ensuring uninterrupted operations and minimizing downtime.

Wax and Scale Inhibitors: Utilizing advanced digital modeling and simulation techniques, our wax and scale inhibitors are specifically formulated to prevent the deposition of waxes and scales in pipelines and processing equipment. These solutions ensure optimal chemical performance, reducing the risk of blockages and maintaining flow efficiency while achieving cost-effective operations. Whether operating in extreme temperatures or high-pressure environments, our inhibitors are tailored to meet diverse operational needs.

Asphaltene Dispersants: Asphaltene deposition can pose significant risks to pipeline integrity, leading to reduced flow and costly maintenance. Our state-of-the-art asphaltene dispersants are engineered to effectively prevent the aggregation and deposition of asphaltenes, ensuring the smooth flow of heavy crude and protecting the long-term integrity of critical infrastructure. These dispersants are highly effective in mitigating operational risks in challenging conditions.

Our integrity management chemical solutions focus on safeguarding the long-term reliability and safety of oilfield equipment and infrastructure, reducing operational risks, and minimizing repair costs.

Corrosion Inhibitors and Cleaners: Corrosion is a major threat to oilfield assets, leading to equipment degradation, safety hazards, and increased maintenance costs. Our corrosion inhibitors are specially developed to protect pipelines, tanks, and other equipment from various forms of corrosion, including microbial-induced corrosion (MIC) and chemical corrosion. Paired with advanced cleaning agents, these solutions help maintain optimal equipment performance and significantly extend asset life, even in harsh environments.

Pipeline Cleaning Solutions: Over time, pipelines accumulate impurities, debris, and deposits that can obstruct flow and reduce efficiency. Our pipeline cleaning solutions are formulated with advanced surfactants and dispersants to effectively remove these blockages, restoring full operational capacity. These cleaning agents are designed to be safe, efficient, and compatible with a wide range of pipeline materials, ensuring seamless maintenance with minimal operational disruption.

Together, our flow assurance and integrity management chemicals offer a comprehensive solution to enhance operational efficiency, reduce downtime, and protect valuable assets across the oil and gas value chain.

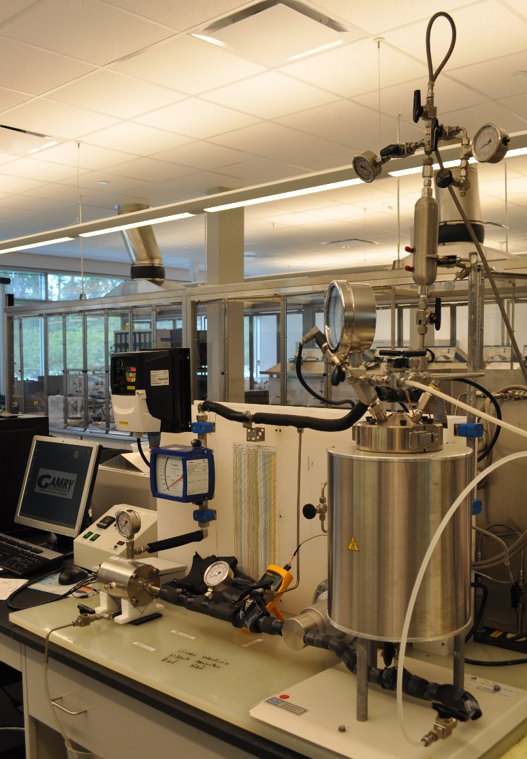

Choose LIU OIL SERVICES as your trusted partner for cutting-edge oilfield chemical solutions that redefine industry standards. Our commitment to industry-leading innovation is reflected in our proprietary technologies and the expertise of our dedicated R&D team, which ensure our products consistently remain at the forefront of the oil and gas sector. By leveraging advanced digital modeling and simulation techniques, we deliver precise, optimized solutions tailored to meet even the most complex operational challenges.

We take pride in offering tailored solutions that go beyond one-size-fits-all approaches. Each chemical formulation and application strategy is custom-designed to address the unique operational requirements and challenges faced by our clients, ensuring maximum efficiency and effectiveness in every scenario.

Environmental responsibility is at the heart of our operations. All of our products are developed with sustainability in mind, utilizing environmentally friendly practices and materials to reduce ecological impact while simultaneously enhancing operational performance. This approach allows us to support our clients in achieving their production goals without compromising on their environmental commitments.

Our comprehensive service model sets us apart, encompassing the entire lifecycle of our chemical solutions. From research and development to production, deployment, and on-site technical support, we provide seamless, end-to-end services. Our team works closely with clients at every stage to ensure solutions are implemented effectively, downtime is minimized, and operational goals are met with professionalism and efficiency.

At LIU OIL SERVICES, we are more than just a service provider—we are your partner in driving innovation, optimizing operations, and building a sustainable future for the oil and gas industry. Let us help you achieve your goals with confidence and reliability.